Stretch Film Factory Custom Logo Wrap

Product description

Quantity per box: 4rolls/6rolls/customized

Customized logo color: 1/2/3 colors

Sample: Free, quick delivery

There are countless hand-made stretch films on the market. How should we judge the quality when choosing hand-made stretch films?

- Test the stickiness of the stretch film

Stretch films are all sticky, which makes the stretch film tightly wrapped around the outside of the product and plays a good protective role on the product. You can take a stretch film for testing, first, fold it twice along a vertical angle, and then press it with your hand and take it out. At this time, we can determine the stickiness of the stretch film based on the difficulty of taking it out and the degree of damage indicated by the stretch film.

- Stretch ratio of stretch film

An important factor in judging the quality of stretch film is the stretch rate. The stretch rate of stretch film is generally in the range of 200%-600%. The method is as follows: stretch the stretch film longitudinally and judge the stretching situation according to the change in force (within the tolerance range of the film, the resistance will show a regular linear change, if it exceeds the range, the resistance will drop sharply). According to this phenomenon, the stretch rate of the stretch film can be determined.

- The surface gloss of the stretch film

The surface gloss will give people a good impression. The raw material purity of good quality stretch wrap film is high, and the surface of the film is fresh and textured. Recycled hand-made wrap film is of poor quality or rough surface, and it feels lifeless. This is because the manufacturer adds excessive magnesium powder and calcium carbonate to cover up impurities in the raw materials, resulting in a relatively hard surface.

The gloss of the stretch film itself will give people a good impression. High-quality stretch film uses high-purity raw materials, so the surface of the film will appear fresh and textured. The quality of recycled stretch film is very poor, the surface will be rough, and it looks lifeless. This situation is generally caused by the manufacturer adding excessive magnesium powder and calcium carbonate to cover up impurities that should not be in the raw materials, resulting in the surface of the film being harder than normal.

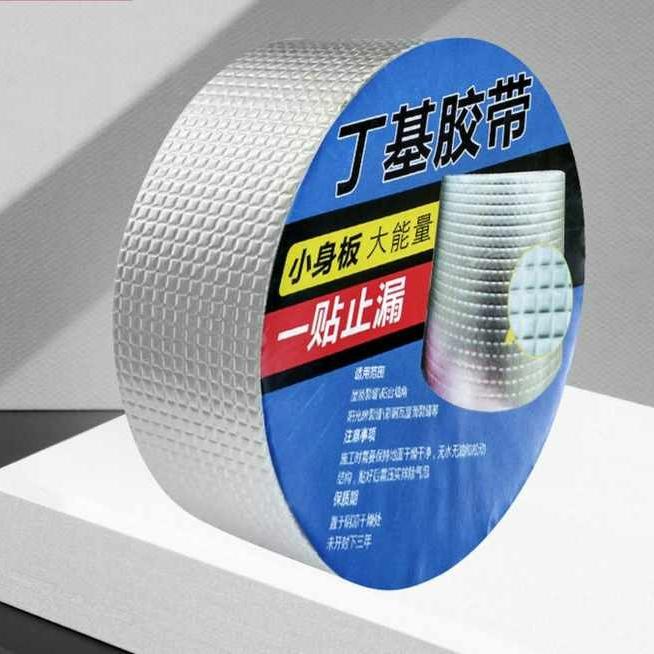

S2's popular products: are butyl waterproof tape; customized cloth-based tape; various warning tapes; high-quality masking tape; various aluminum foil tapes; customized stretch film; and foam double-sided tape.